743 ans d'expérience cumulée

Confiance, engagement, intégrité, efficacité

Être un leader technologique et industriel indépendant et responsable

Une entreprise où chacun peut trouver sa place et s'épanouir

Les métiers

Nexteam est un acteur intégré au service du secteur aéronautique et défense avec une expertise complète des pièces métalliques au travers de 4 métiers : l’usinage, la fonderie, la mécano-soudure, et le traitement de surface. Le Groupe intervient dans le cadre de programmes longs ou dans l’urgence, du co-engineering à la série, en phase de construction ou de réparation.

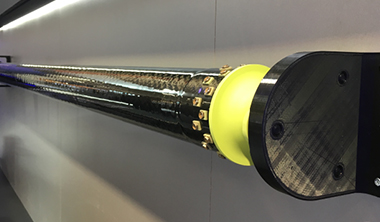

Le cœur d’activité est la fabrication de pièces et sous-ensembles mécaniques à forte valeur ajoutée, prototype ou en série, pour les grands programmes aéronautiques et de défense. Fort de son expertise métier, Nexteam conduit également une activité de bureaux d’étude intégrés et dispose d’une équipe dédiée à l’innovation qui l’amène à développer des produits, de la conception à la réparation. Des activités d’assemblage, de maintenance et réparation sont également proposées.

Nexteam dispose de 3 expertises métiers dont fait partie notre division Fonderie (Foundry).

Nexteam dispose de 3 expertises métiers dont fait partie la division Usinage (Machining).

Nexteam dispose de 3 expertises métiers dont fait partie notre division Mecano-Soudure (Sheet-Metal).

Nexteam intervient dès la phase d'étude et de conception pour proposer à ses clients des projets clés en main jusqu'à l'industrialisation de solutions optimisées. Le métier d'engineering se fait en étroite collaboration avec les bureaux des Méthodes.

Certifié EN9100, Nexteam développe une expertise spécifique dans le domaine des procédés spéciaux pour les traitements de surface, qui lui permet de répondre aux besoins des clients avec une grande réactivité.

Nexteam intègre des sous-ensembles de structure et des sous-ensembles mécaniques, hydrauliques ou pneumatiques afin de fournir à ses clients des produits finis prêts à être montés sur les appareils.

Nexteam transforme et stocke les matières premières spécifiques à l'aéronautique (Inox, titane, inconel, lithium) pour ses sites de production et clients.

Le service AOG répond aux besoins de production de pièces mécaniques en urgence, dans des délais très courts et avec la garantie de qualité de Nexteam.

Nexteam intervient en MRO sur les pièces de structure pour le compte de compagnies aériennes et d'avionneurs.